Bush Conveyor Chains by KS Kneissl & Senn Technologie GmbH – Robust Solutions for Industrial Conveyor Systems

KS Kneissl & Senn Technologie GmbH offers high-quality bush conveyor chains in accordance with DIN 8167 (M series) and DIN 8165 (FV series) standards. These articulated conveyor chains are known for their durability and precision, making them ideal for demanding applications in power generation, the wood and particle board industries, and various other industrial sectors.

Since 2022, we have been manufacturing at our state-of-the-art facility in Erl, equipped with a fully modernized machine park. This enables us to process a wide range of materials — from steel and stainless steel to wear-resistant specialty alloys — with high precision, ensuring robust and long-lasting components for conveyor technology.

more informations contact us

High-Quality Materials for Maximum Service Life

Our bush conveyor chains are manufactured from carefully selected case-hardened steels:

Pins & Bushings: Ck15, 16MnCr5, 42CrMo4, 1.4301 (AISI 304)

Rollers: Ck15, Ck45, 16MnCr5, 42CrMo4

Link Plates: Ck45, 30MnB5, 42CrMo4

These components are hardened or tempered depending on the material used, resulting in increased wear resistance and durability. Pins and bushings are flattened to prevent rotation as standard, and the pins are either riveted or welded to ensure a secure connection.

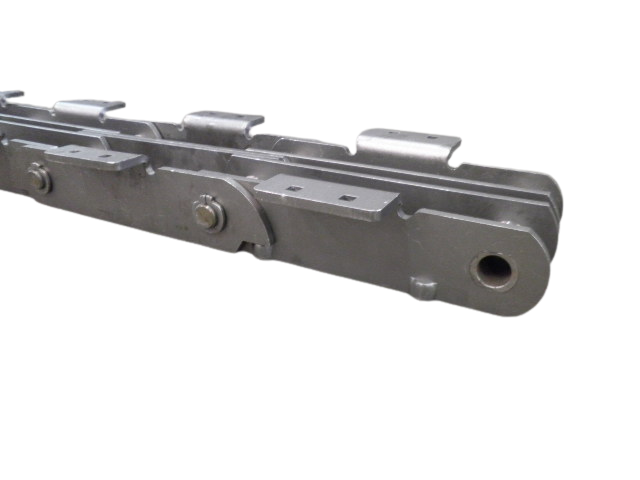

Bush Conveyor Chains

Reliability and durability for demanding conveying processes

Our bush conveyor chains are characterized by a robust design, high wear resistance, and precise manufacturing. Whether used in heavy industry, bulk material handling, or specialized transport applications – we provide customized solutions that are precisely tailored to your requirements.

With decades of experience and an uncompromising commitment to quality, we set the standard in modern conveyor technology.

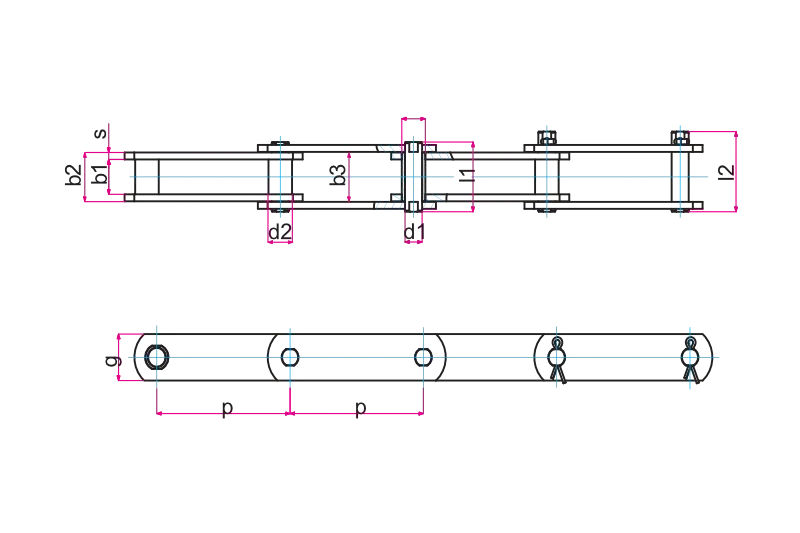

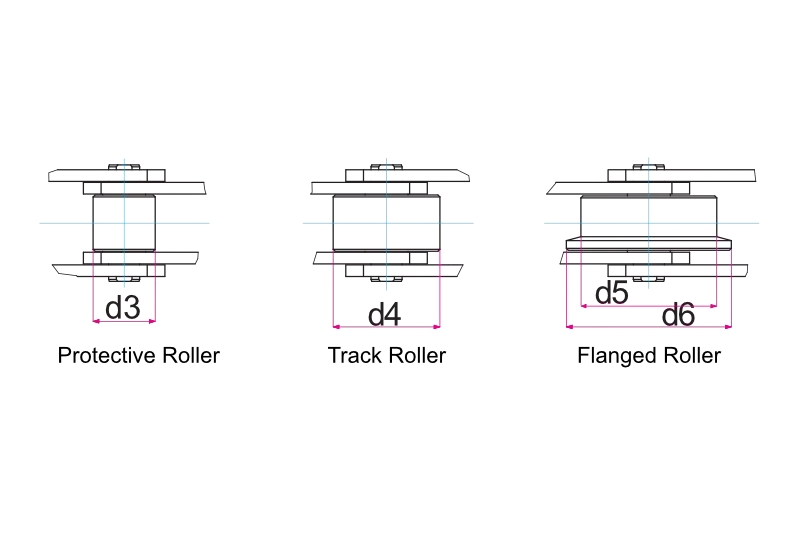

Types of Chains

FV Series (DIN 8165)

| ISO | p | b1 | b2 | b3 | d1 | d2 | d3 | d4 | d5 | d6 | l1 | l2 | g | s | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FV 40 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | – | 18 | 24,5 | 25,0 | 10 | 15 | 20 | 32 | 40 | 48 | 37 | 44 | 26 | 3 |

| FV 63 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | – | 22 | 30,5 | 31,0 | 12 | 18 | 26 | 40 | 50 | 60 | 46 | 55 | 30 | 4 |

| FV 90 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 25 | 35,5 | 36,0 | 14 | 20 | 30 | 48 | 63 | 73 | 53 | 62 | 35 | 5 |

| FV 112 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | - | 30 | 42,5 | 43,0 | 16 | 22 | 32 | 55 | 72 | 87 | 53 | 72 | 40 | 6 |

| FV 140 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 35 | 47,5 | 48,0 | 18 | 26 | 36 | 60 | 80 | 95 | 68 | 80 | 45 | 6 |

| FV 180 | - | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 45 | 61,5 | 62,5 | 20 | 30 | 42 | 70 | 100 | 120 | 86 | 100 | 50 | 8 |

| FV 250 | - | - | 125 | 160 | 200 | 250 | 315 | 400 | 55 | 72,0 | 73,0 | 26 | 36 | 50 | 80 | 125 | 145 | 98 | 114 | 60 | 8 |

| FV 315 | - | - | 125 | 160 | 200 | 250 | 315 | 400 | 65 | 86,0 | 87,0 | 30 | 42 | 60 | 90 | 140 | 70 | 117 | 133 | 70 | 10 |

| FV 400 | - | - | - | 160 | 200 | 250 | 315 | 400 | 70 | 96,0 | 97,0 | 32 | 44 | 60 | 100 | 150 | 185 | 131 | 141 | 70 | 12 |

| FV 500 | - | - | 160 | 200 | 250 | 315 | 400 | 500 | 80 | 106 | 107 | 36 | 50 | 70 | 110 | 160 | 195 | 141 | 151 | 80 | 12 |

| FV 630 | - | - | - | 200 | 250 | 315 | 400 | 500 | 90 | 116 | 117 | 42 | 56 | 80 | 120 | 170 | 210 | 153 | 163 | 100 | 12 |

M Series (DIN 8167)

| ISO | p | b1 | b2 | b3 | d1 | d2 | d3 | d4 | d5 | l1 | l2 | g | s | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M 20 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 16 | 22 | 22,2 | 6,0 | 9,0 | 12,5 | 25 | 30 | 35 | 49 | 18 | 2,5 |

| M 28 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 18 | 25 | 25,2 | 7,0 | 10,0 | 15,0 | 30 | 36 | 40 | 56 | 20 | 3,0 |

| M 40 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 20 | 28 | 28,3 | 8,5 | 12,5 | 18,0 | 36 | 42 | 45 | 63 | 25 | 3,5 |

| M 56 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 24 | 33 | 33,3 | 10,0 | 15,0 | 21,0 | 42 | 50 | 52 | 72 | 30 | 4,0 |

| M 80 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 28 | 39 | 39,4 | 12,0 | 18,0 | 25,0 | 50 | 60 | 62 | 86 | 35 | 5,0 |

| M 112 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 32 | 45 | 45,5 | 15,0 | 21,0 | 30,0 | 60 | 70 | 73 | 101 | 40 | 6,0 |

| M 160 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | 37 | 52 | 52,5 | 18,0 | 25,0 | 36,0 | 70 | 85 | 85 | 117 | 50 | 7,0 |

| M 224 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | 43 | 60 | 60,6 | 21,0 | 30,0 | 42,0 | 85 | 100 | 98 | 134 | 60 | 8,0 |

| M 315 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 48 | 70 | 70,7 | 25,0 | 36,0 | 50,0 | 100 | 120 | 112 | 154 | 70 | 10,0 |

| M 450 | - | 200 | 250 | 315 | 400 | 500 | 630 | 56 | 82 | 82,8 | 30,0 | 42,0 | 60,0 | 120 | 140 | 135 | 185 | 80 | 12,0 |

| M 630 | - | 200 | 250 | 315 | 400 | 500 | 630 | 66 | 96 | 97,0 | 36,0 | 50,0 | 70,0 | 140 | 170 | 147 | 200 | 100 | 14,0 |

| M 900 | - | - | 250 | 315 | 400 | 500 | 630 | 78 | 112 | 113,0 | 44,0 | 60,0 | 85,0 | 170 | 210 | 167 | 220 | 120 | 16,0 |

Additional Types

- FV Series

- with carrier plates

- with hollow pins

- with mounting lugs

- with bent or welded scrapers

On request, we also offer:

- with increased articulation clearance

- with enhanced strength

- galvanized or stainless steel versions

- sprockets

Custom designs based on your individual drawing available upon request.

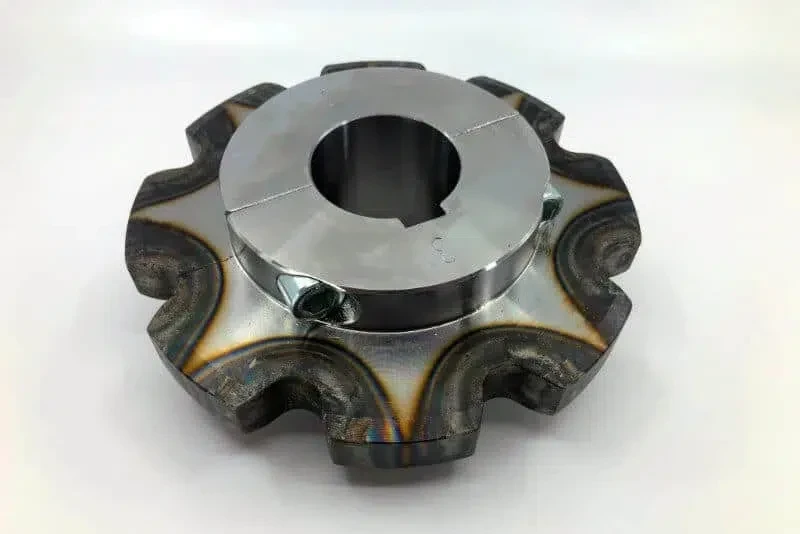

Sprockets

DIN Standards | Custom Solutions

At KS Kneissl & Senn Technologie GmbH, we manufacture a full range of sprockets in compliance with DIN standards and also offer custom sprocket designs tailored to your specific requirements. All sprockets are produced with high precision, using durable materials to ensure long-lasting performance in demanding industrial applications.

On request, our sprockets are also available with hardened teeth for increased wear resistance and extended service life.

Available Sprocket Types:

Sprocket discs (tooth discs without hub)

Sprockets with single-sided hub

Sprockets with double-sided hub

Custom sprockets according to your drawing or specification

Whether you need drive sprockets for forged link chains, idler wheels, or special geometries for complex conveyor systems – we deliver precision-engineered sprockets for reliable and efficient power transmission.

Anwendungsbereiche

Our robust conveyor chains are used across various industrial sectors:

Versatile Applications – For Maximum Efficiency in Material Handling

Our systems are as flexible as your requirements. KS Kneissl & Senn conveyor chains are ideally suited for use in:

Reclaimers for clinker, gypsum, and clay

Scraper conveyors for heavy-duty materials

Transport of roundwood and wood chips

Automated sawmill lines

Conveying systems for coal, biomass, slag, and quartzite

Handling of polymers and granulates

Bottle and container transport

Glass shard scraper chains – specifically for the glass industry

…and many other industrial applications

Reliable Technology Across Diverse Industries

Our robust solutions deliver proven performance in numerous industries – trusted worldwide in:

Cement and concrete plants

Steel and metal industries

Raw material and mineral processing companies

Wood processing and paper production

Power plants and energy providers

Environmental and recycling technology operations

Food and beverage industry

Chemical and fertilizer production

Glass manufacturing and processing

...and many other sectors with demanding conveyor requirements

Why Choose KS Kneissl & Senn Technologie GmbH?

With over three decades of experience in conveyor technology, KS Kneissl & Senn Technologie GmbH stands for precision, reliability, and custom solutions. Since 1988, we have been a trusted partner for industrial conveying systems – across Europe and beyond.

What sets us apart:

Quality: We use certified European steels to ensure maximum durability and performance

Precision: Automated manufacturing guarantees consistent product quality

Flexibility: We develop tailor-made solutions to meet your exact technical and operational needs

Experience: Decades of hands-on expertise and innovation in conveyor chain production

Speed & Service: Fast turnaround times and a customer-first mindset

DIN Standards Compliance: Reliable performance backed by proven norms

Choose KS Kneissl & Senn – where expertise meets engineered excellence.

Machinery

Precision and performance thanks to state-of-the-art machinery

Here you’ll find impressions of our machinery.

Our machine park is continuously being expanded with new equipment.

If you have any questions about our machines or processing capabilities, please don’t hesitate to contact us.

We look forward to supporting you with your next project.

About us

KS Kneissl & Senn Technologie GmbH

Your one-stop shop for lubricants, sealing solutions, foundry supplies, insulation systems, as well as conveyor chains and expansion joints.

Our Product Portfolio:

Conveyor Chains

Sealing Solutions

Chesterton Products

Foundry Supplies

Refractory Materials

Expansion Joints

Plain Bearings

Logistics Solutions

Metal Fabrication

Key Figures of the Group

- The SENN Group is the umbrella brand of Senn Beteiligungs GmbH. The group consists of several companies operating in the field of industrial supplies and was founded in 2001. Within the group, we are able to offer you everything from a single source – efficient, coordinated, and customer-focused.Click the button below to learn more about our products and business areas.Group Key Figures:

- Annual Revenue: €32 million

- Employees: 100

- Locations: Austria and Germany

- Founded: 2001

Job highlight

CNC Machinist – Turning / Milling

We are an innovative company in the field of metal processing and are currently looking for a dedicated and qualified CNC Turning and Milling Technician to join our team as soon as possible.

In this role, you will be a key player in our production process.